Introduction to Dry Ice Temperature Shipping

Imagine a world where savoring Alaskan salmon in New York or enjoying Belgian chocolate in Sydney is an everyday luxury. Thanks to the power of dry ice, this is our reality.

Journey with Cold Chain 3PL as we delve into the chilly depths of frozen shipping, unraveling the icy enigma that is dry ice – a game-changer in the transportation of perishable goods. From its unique properties and production to its critical role in global logistics and dry ice temperature shipping, this guide illuminates the multifaceted role of dry ice in our interconnected world.

Dry ice, known scientifically as the solid form of carbon dioxide (CO2), has significantly impacted the frozen shipping industry. This unique substance offers a range of advantageous qualities, most notably its cooling capabilities and the absence of a liquid phase, making it instrumental in preserving and transporting perishable goods.

The Fundamental Science Behind Dry Ice Temperature Shipping

Unlike most solids, dry ice does not melt into a liquid but undergoes a process known as sublimation, transitioning directly from a solid state into a gas. This transformative process happens at a notably low temperature, -78.5 degrees Celsius to be exact, ensuring a consistently frigid environment ideal for shipping frozen goods, especially within cold storage warehousing.

Dry ice is produced through a procedure that involves pressurizing and cooling gaseous carbon dioxide until it solidifies. The solid carbon dioxide is then molded into various forms – most commonly blocks or pellets – to cater to different applications, one of which is in the realm of frozen freight shipping.

Dry ice offers a range of appealing characteristics for dry ice temperature shipping. One is that its gaseous state leaves no water residue behind, unlike conventional ice. This is a significant advantage in the shipping world, where unwanted moisture can cause considerable damage to products in transit.

Why Use Dry Temperature Logistics

Dry ice is often the coolant of choice in frozen shipping for several reasons. Its low temperature can maintain the quality of products, extending their shelf life during transportation. Furthermore, its non-residual nature eliminates the need for powered refrigeration, thus enhancing the efficiency of cold chain fulfillment by reducing energy consumption.

When compared to traditional ice, dry ice proves superior in many respects. It provides longer-lasting cooling, eliminates moisture-related issues, and requires less volume due to its greater cooling capacity. These advantages make dry ice an efficient and effective choice in the shipping industry.

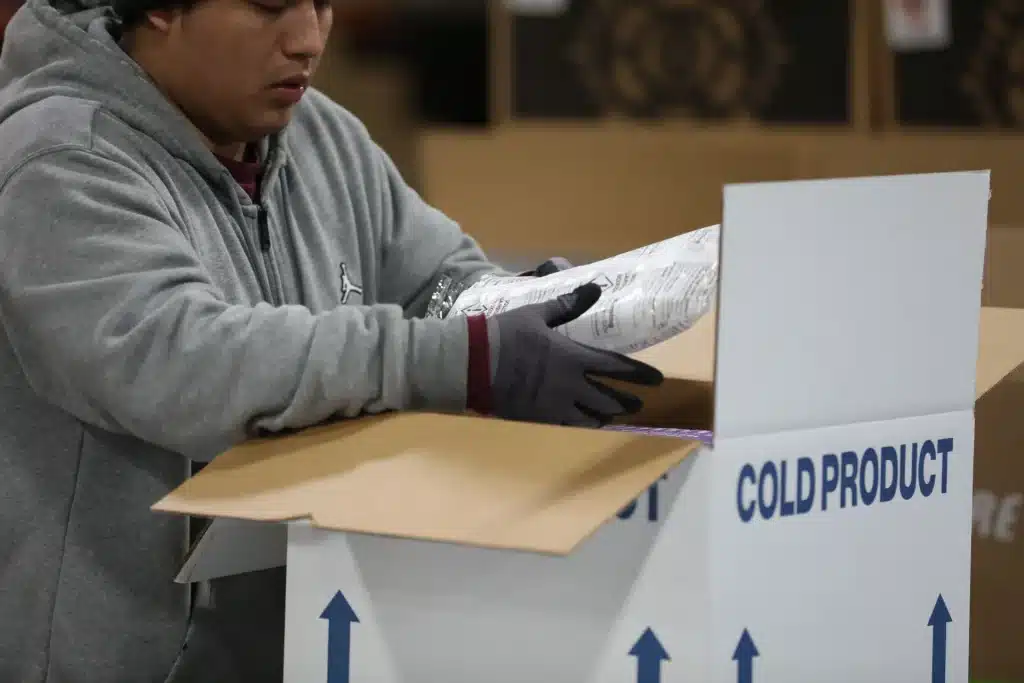

Despite its many benefits, handling dry ice necessitates adherence to strict safety protocols. Exposure to dry ice can lead to frostbite due to its extreme coldness, while inhalation of excessive carbon dioxide gas can cause asphyxiation. Therefore, effective ventilation and the use of personal protective equipment are essential during handling and storage.

Although dry ice is highly beneficial, it also presents some limitations. Its extreme cold and the potential for rapid gas expansion upon sublimation make it a potential hazard, requiring thorough training for handling and careful storage considerations. Additionally, the shipping industry faces challenges in disposing of any leftover dry ice in a safe, eco-friendly manner.

The Evolution and Growth of Dry Ice Temperature Shipping

Over time, the role of dry ice in shipping has evolved alongside technological advances and market demand changes. Initially used primarily for the preservation of food, dry ice has since expanded its reach to include secure medical shipping and the transportation of medical and biological materials, including vaccines and lab samples.

Dry ice’s role in vaccine transportation gained particular attention during the COVID-19 pandemic. Many vaccines, including the Pfizer-BioNTech vaccine, required ultra-cold shipping conditions, achievable only through the use of dry ice.

The Environmental Impact of Dry Ice Temperature Shipping

Environmental considerations are vital when assessing the impact of dry ice. Dry ice releases carbon dioxide, a known greenhouse gas, when it sublimates. However, it’s important to note that the carbon dioxide used in the production of dry ice is often a by-product of other industrial processes, making it essentially a form of recycling.

Optimizing Dry Ice Temperature Shipping for Cost and Efficiency

Optimization of dry ice usage requires a balance of product safety, cost-effectiveness, and environmental considerations. This involves thoughtful package design, proper insulation, efficient loading techniques, and understanding how varying transportation conditions might affect sublimation rates, which are all crucial aspects of cold storage solutions.

Despite the benefits, dry ice can be costly, and these costs extend beyond the product itself. Incorporating dry ice into a shipping strategy involves expenses related to employee training, equipment for safe handling, storage, and the cost associated with any product damage due to improper use.

The Role of Dry Ice Temperature Shipping in Food and Beverage Fulfillment

In the realm of food shipping, dry ice is invaluable. It allows for the safe and quality-preserving transport of perishable items, such as meat, fish, and dairy, making it an essential part of cold chain fulfillment. Additionally, it makes long-distance shipping of frozen gourmet items possible, opening up global culinary possibilities.

Legal and Regulatory Considerations in Dry Ice Temperature Shipping

Dry ice shipping requires the navigation of various legal and regulatory landscapes, particularly in cold storage warehousing and transport. Authorities classify dry ice as a hazardous material, meaning transport is subject to numerous restrictions, including those pertaining to package labeling, quantity limitations, and necessary documentation.

The Future of Dry Ice Temperature Shipping

Looking forward, dry ice is poised to maintain its crucial role in frozen shipping. Market demands and technological innovations will likely shape its future, with the industry continuously seeking ways to improve efficiency, reduce costs, and minimize environmental impact.

Technological advancements play a substantial role in enhancing dry ice shipping. Innovations related to packaging materials, temperature tracking devices, and automatic handling systems are continually improving this shipping method’s safety, efficiency, and reliability.

The rise and success of meal kit delivery services demonstrate the power and reliability of dry ice shipping. These services bank on dry ice’s capabilities to ensure their fresh ingredients maintain the quality during transit, thus promising consumers a safe, fresh, and convenient dining experience.

Precautions and Best Practices in Dry Ice Temperature Shipping

Adhering to best practices in dry ice shipping can greatly reduce the risk of accidents. This involves safe handling and storage, adequate ventilation, the use of proper insulation, and, importantly, training staff in safety procedures and regulatory compliance.

In closing, dry ice has established itself as an indispensable asset in the world of frozen shipping. Despite its challenges, it remains unmatched in its ability to preserve the quality of perishable goods in transit. The industry can expect continued evolution and innovation in response to technological advancements and shifting market demands, ensuring that dry ice will remain a crucial player in the future of frozen shipping.

Jamie Moriarty is an experienced entrepreneur that has founded companies in consumer packaged goods, (Uber Dispensing Co.) technology, (Pauwow) and brokerage and consulting (R.F.Queue).